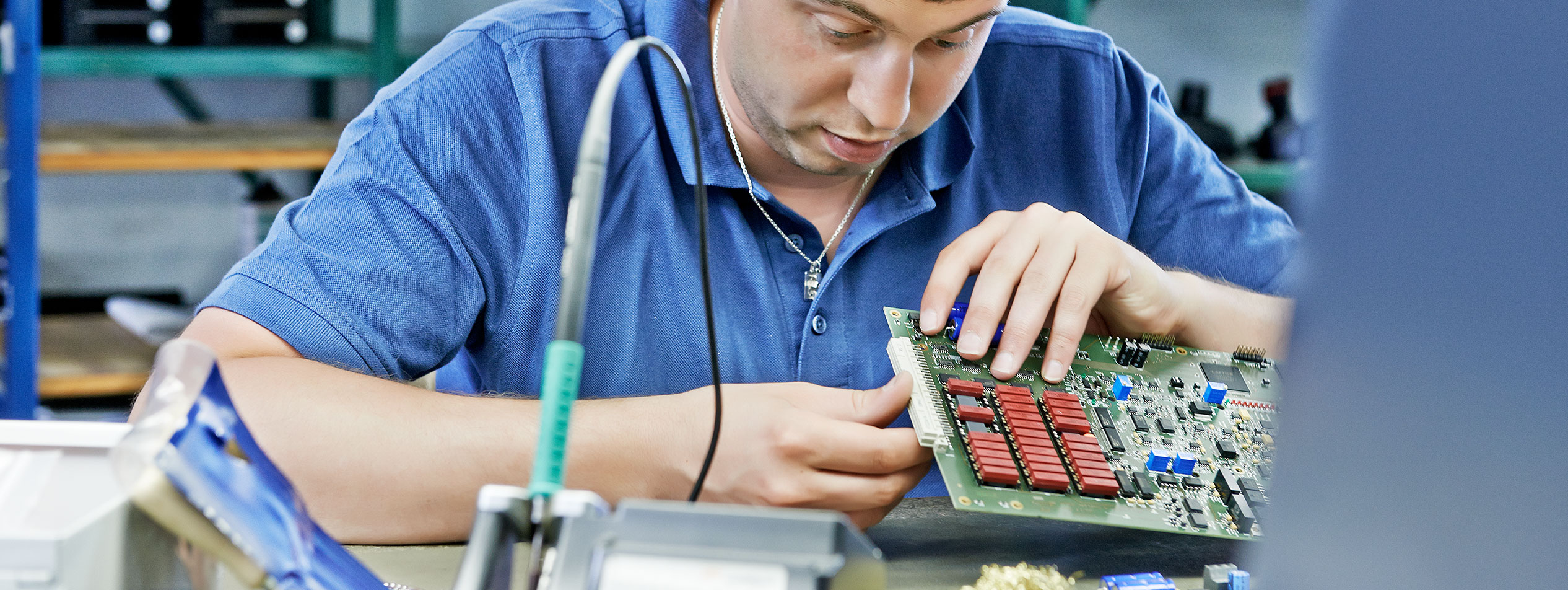

In the field of electronic contract manufacturing our customers can rely on on-demand services ranging from EMS (Electronic Manufacturing Services) to EES (Electronic Engineering Services).

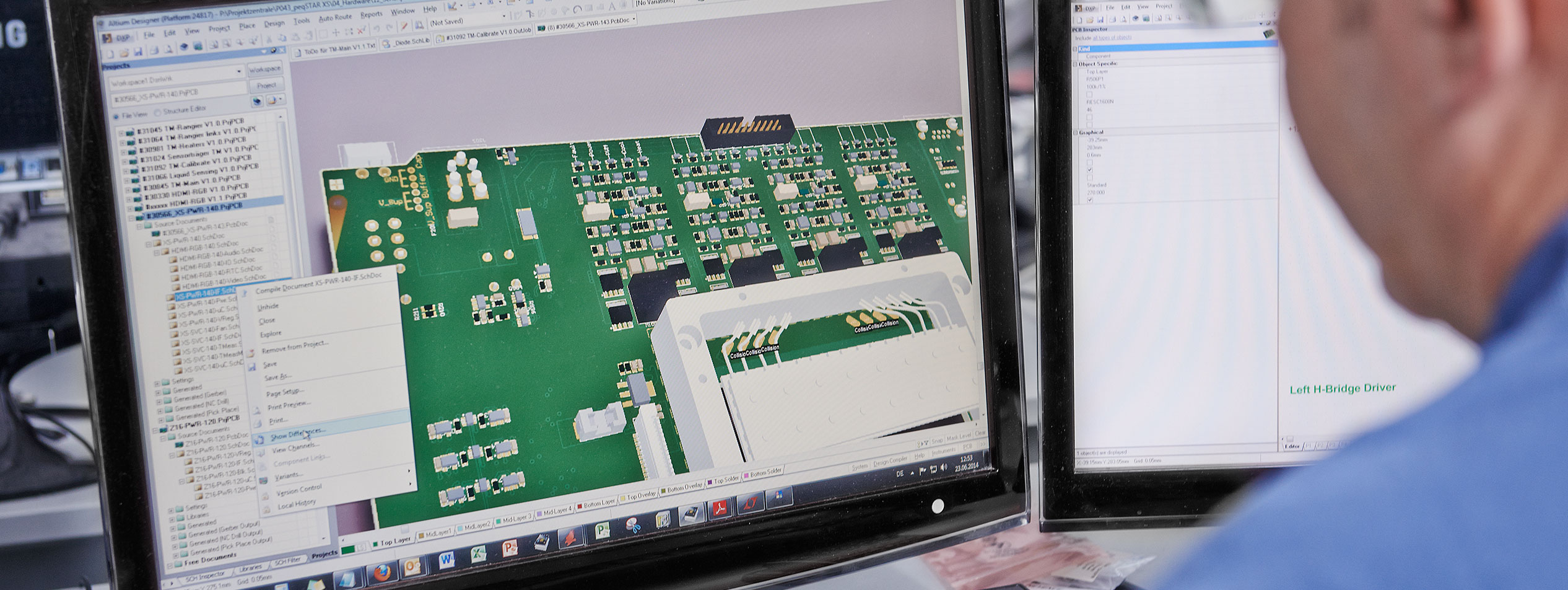

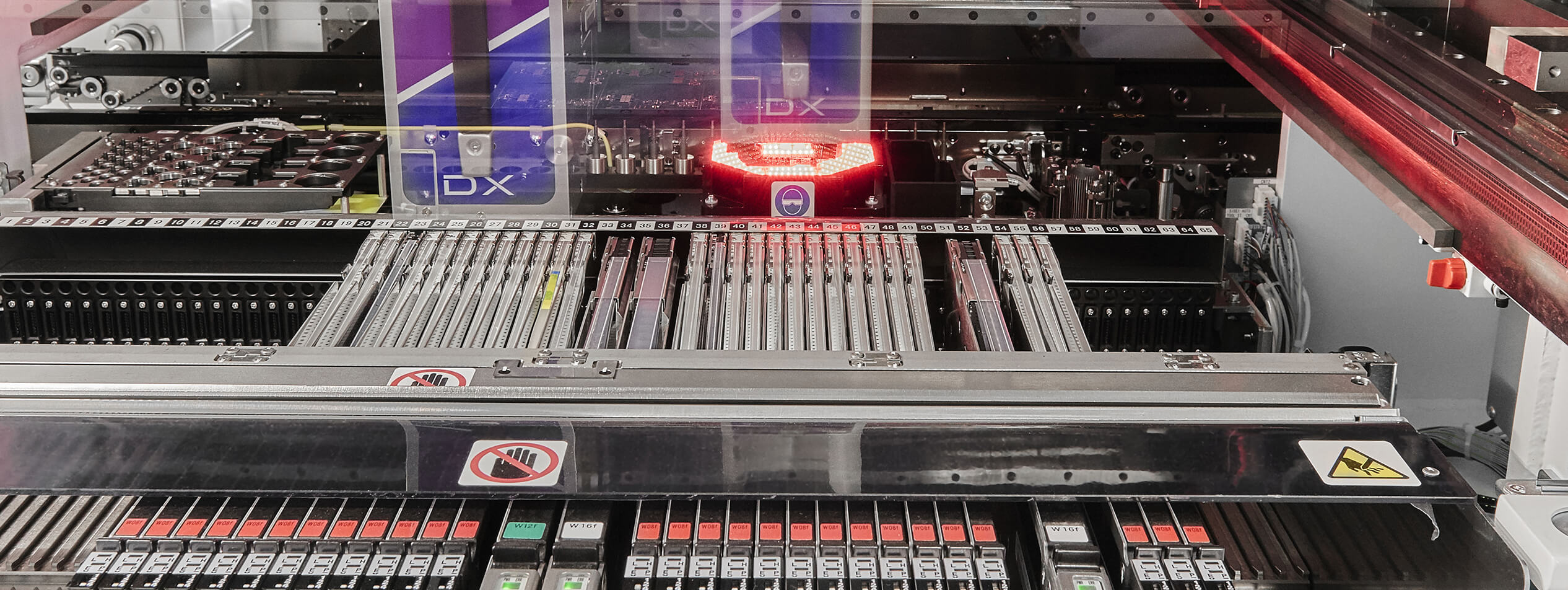

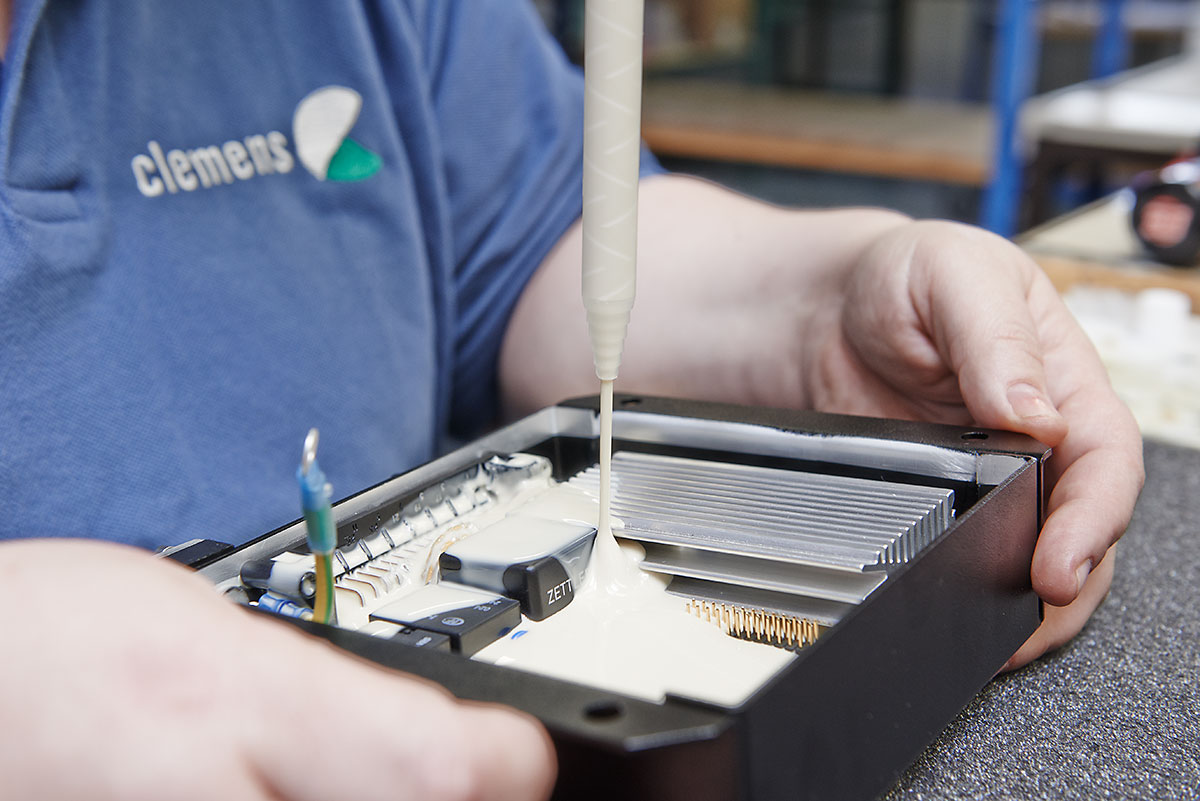

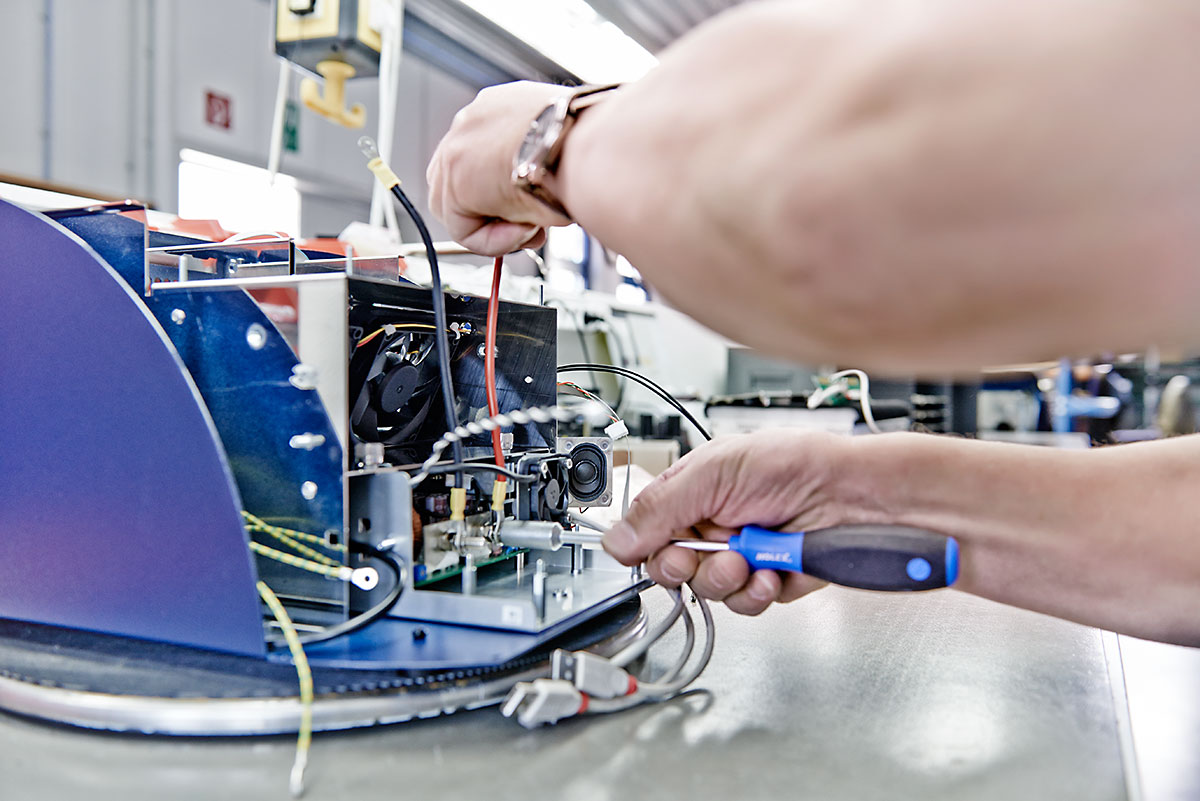

According to the customer’s request we handle the PCB design, the design of complete electronic systems or PCBs, re-design and Prototyping. Once a sample is approved the production process is handled automatically by our modern machinery. We manufacture cost effective / low-cost prototypes and small volumes, as well as quantities of 5,000 to 10,000 units per year. Across up to 4 Laserlite placement tables we assemble conventional wired components which are then finished on a double-wave soldering machine with 450 mm working width and integrated spray fluxing.

We are certified according to EN ISO 9001/2015 and EN ISO 13485/2016 and see ourselves as a specialist with the highest quality standards.